About us

- Home

- About us

About us

The next generation composites for infrastructure

Our strength lies in our ability to mobilize skilled and certified personnel, including Inspectors, Technicians, Engineers, and Supervisors, backed by a structured operational process to meet client expectations efficiently and cost-effectively. We maintain a high level of professional governance, transparent communication, and strict compliance with Saudi labor and industrial regulations.

At Al Ruwad, we believe in building long-term partnerships through reliability, responsiveness, and a commitment to excellence. By combining industry expertise with modern operational practices, we ensure our clients receive consistent support throughout the duration of their projects, from mobilization to completion.

Core Competencies

-

Technical Manpower Supply (GIS, Inspection & EPC Categories)

-

Industrial Testing & Inspection Coordination

-

Aramco & EPC Project Support Services

-

Rapid Mobilization & Visa Processing Support

-

Project Resource Management & Operations Control

Our Commitment

-

Quality Execution

-

On-Time Mobilization

-

Regulatory Compliance

-

Client-Centric Communication

-

Value-Driven Partnership

Industries We Provide

Turnkey Solutions

-

Acid Pickling / Acid Regeneration

-

Rayon / Staple Fiber

-

Chemical

-

Soda Ash

-

Chloro-Alkali

-

Engineering Procurement

-

Fertilizer

-

Contractors

-

Oil / Gas

-

Water / Waste Water / Effluent

-

Paper / Pulp

-

Sewage Treatment

-

Petrochemical / Oil Refinery

-

Zinc / Copper Refineries

-

Pharmaceuticals

-

Infrastructure

-

Power Plants

-

Transportation

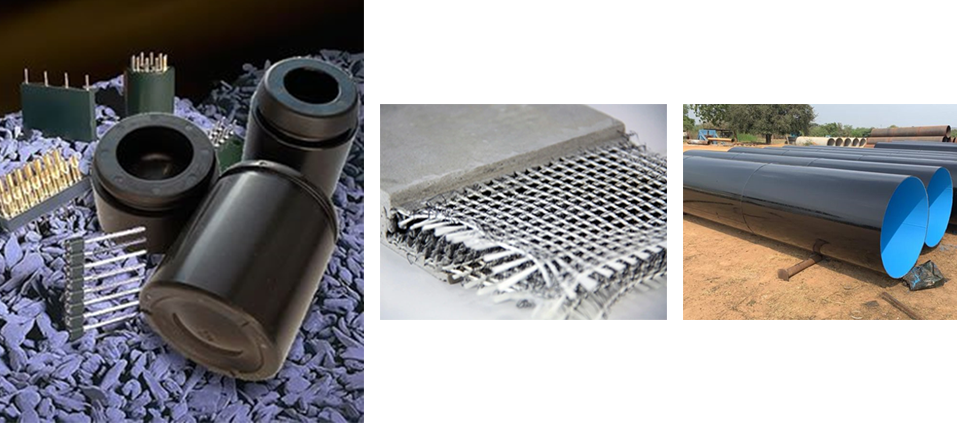

Materials We Handle

THERMOSET

-

FRP (Fiber Reinforced Plastic)

-

GRP (Glass Reinforced Plastic)

-

FURANE

-

PHENOLIC

-

EPOXY

Materials We Handle

THERMOPLASTIC LINERS

-

PVC (Polyvinyl Chloride)

-

CPVC (Chlorinated Polyvinyl Chloride

-

PP (Polypropylene)

-

PVDF (Polyvinylidene Fluoride)

-

ECTFE (Ethylene Chloro Tri Fluoro Ethylene)

-

FEP (Fluorinated Ethylene Propylene Copolymer)

-

PFA (Per Fluoro Alkoxy)

Our Differentiation

All our FRP/GRP products are manufactured by SINGLE PIECE MOULDING process without any joints and with mirror finish inside to give superior quality and better performance.

-

All our Thermoplastic lined equipment are provided with Conductive Layer, so that any damage on the thermoplastic welding can be identified and future maintenance will become easy.

-

The outside surface of all our products are provided with a special coating (proprietary) which ensures a Long Life with same finish during its life time without any additional cost.

-

Our products are guaranteed for trouble-free performance for minimum 15 years with a design life of 15–50 years.

-

All our products are provided with UV Resistant coating.

Product Range

-

Chemical Process Equipment

up to 7000mm Dia – 35000mm height

-

Pipes and Fittings

up to 4000 mm dia

-

Reaction Vessels, Mixing Vessels

up to 15000mm Dia × 15000mm height

-

RO Membrane Housing & Pressure Vessels

upto 24" × 12000mm long

-

Gratings Moulded / Pultruded

-

Cable Trays

up to 1000 mm Width

-

Damper Valve (100% Leak Proof)

-

Chemical Storage Tanks

up to 15000mm Dia × 15000mm height

-

Polymer Concrete Cells

up to 15000mm Dia × 15000mm height

-

Wet Gas Electrostatic Precipitator (ESP) Pollution Control System

(Scrubber, Absorber, Tower, Separator, Blower (FAN), Stacks, Ductings etc. (Maximum 6000mm Dia × 30000mm height))

-

Glass Flake Lining

-

Corrugated / Cladding Sheets

-

Pultruded Sections